A text might also have some useful empirical data. You probably need to consult a text book to find a more detailed explanation and formulae. You won't be able to determine how much copper loss is tolerable without knowing the wire temperature rating, the other losses and the heat transfer characteristics of the motor. To calculate that, you need all of the design characteristics of the motor including stator and rotor resistance and leakage reactance, magnetizing reactance and iron loss. Test resistance (ohms)between two phases at a time, and comparing all three phase combinations resistances. If the copper loss is too high, select a winding distribution that is more efficient. With the 3 phase wire leads (heavy gauge wires) disconnected from everything, and not moving or turning the motor.

To calculate the wire size, you would calculate the maximum size would fit in the slots.

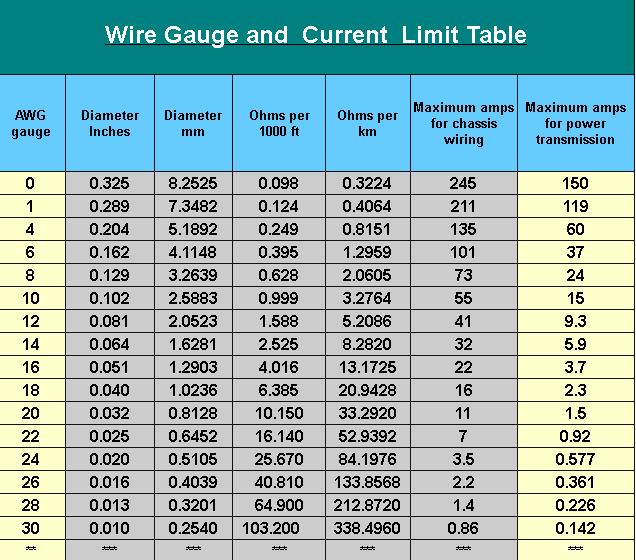

To get a more accurate number of winding turns, you would need to consider the length and reluctance of the magnetic circuit in the iron and the effects of the slot size and geometry on the magnetic circuit. That would allow you to calculate an approximate number of winding turns for each winding distribution alternative that you wish to consider. The n gauge wire diameter d n in millimeters (mm) is equal to 0. Select from wire tables a gauge that will carry that current. Work out the current from amps watts / volts. Usage/Application Electric Elongation 30-40 Diameter/Size 0.40 - 1.60. You can then work out the number of turns needed. Poly Winding Wires, Motor Winding Wires, Submersible Winding Wire offered.

When you spin the alternator at its expected lowest operating RPM, measure the open circuit voltage produced. The n gauge wire diameter d n in inches (in) is equal to 0.005in times 92 raised to the power of 36 minus gauge number n, divided by 39. Find the numbers by winding a 10 turn coil from thin wire. If you know the maximum flux density and the size of the air gap, you can calculate the air-gap flux per pole. Wire gauge calculations Wire diameter calculations.

0 kommentar(er)

0 kommentar(er)